The friendliest digital twin platform for manufacturing

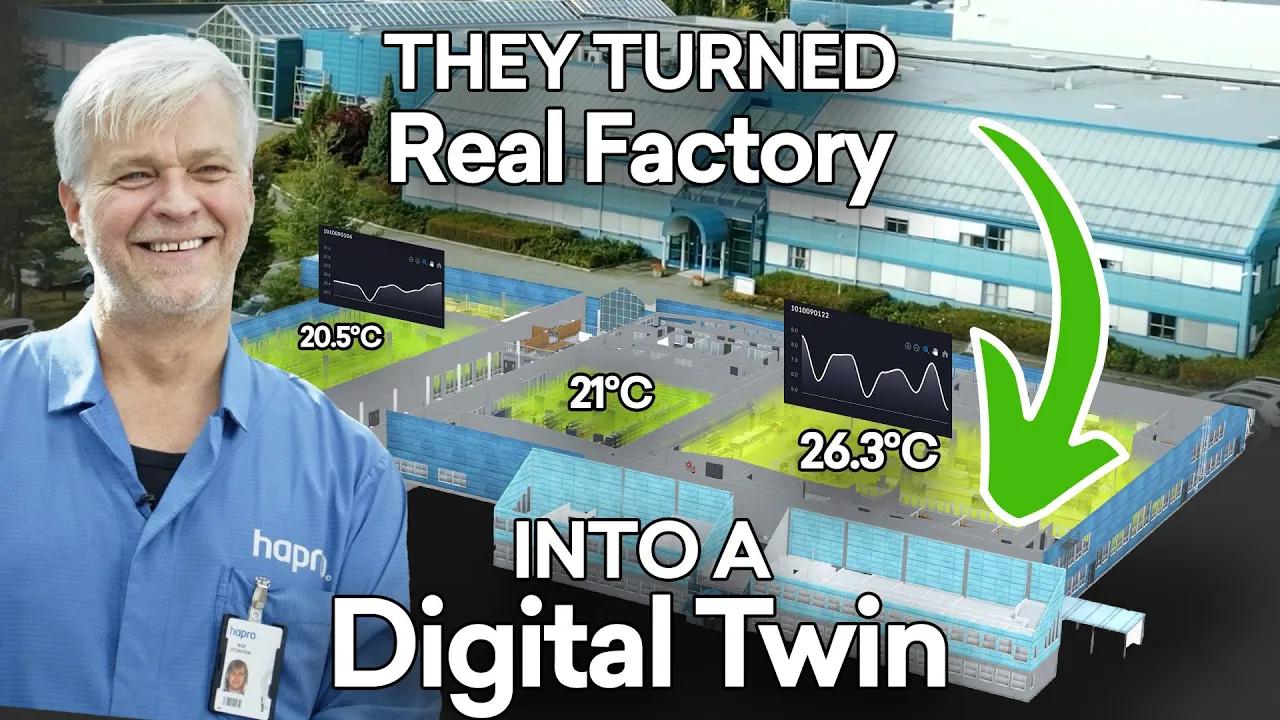

Effortlessly plan, simulate, and optimize operations, through the help of an interactive 3D model of your factory.

Upload 3D model of your building or order one

Upload your model in a form of a Revit's RVT, NWF, or any other popular 3d file (FBX, OBJ, IFC, STEP, etc.)

Connect Sensors Data, IoT, ERP, and MES Systems

Seamlessy connect your own sensors and API's to transfer your data directly to your 3d model.

Visualize & Outperform the Competitors

Boost your ROI and increase factory efficiency. Visualize all data in one centralized place for broader view

Design the Factories of the Future

Our Partners

Tore Flaterud

COO, Isiflo

Dominik Palka

Senior Process Engineer, Vigo Photonics

Inge Storstein

Lean Coordinator, Hapro Electronics

Why Choose Moicon

Smart visualization and real-time tools built for manufacturing teams.

Save Time, Cut Costs

Visualize your factory instantly. Reduce time spent switching between tools, emails, and spreadsheets.

Fast Onboarding

Get your factory model up and running in hours not weeks. Designed for ease, even if you've never used 3D tools.

Live Operational Insights

Make smarter decisions with live data and actionable insights, delivered in real-time to stay ahead of the curve

Web-Based

Moicon runs in your browser. No downloads, no setup time. Just log in and start optimizing your factory.

Ready to transform your Factory?

Start your journey towards a smarter, more efficient manufacturing process with Moicon today.